We are having our own and Tie-up facilities to speed up all the process, to meet customer requirements and to maintain the time line.

To process cotton, Polyester and blended fabrics, we have the advanced HTHP cheese dyeing division. Equipped with machinery from Thies, Germany, Brozoli Italy. Our OEKO-TEX and GOTS certified fabric dyeing division has a modern Effluent Treatment Plant & Reverse Osmosis Technology, and Biological treatment technologies and Nano Technology reinforcing our commitment to eco-friendly practices. (Zero Liquid Discharge)

To process cotton, Polyester and blended fabrics, we have the advanced HTHP cheese dyeing division. Equipped with machinery from Thies, Germany, Brozoli Italy. Our OEKO-TEX and GOTS certified fabric dyeing division has a modern Effluent Treatment Plant & Reverse Osmosis Technology, and Biological treatment technologies and Nano Technology reinforcing our commitment to eco-friendly practices. (Zero Liquid Discharge)

Capacity

Printing is one of our chief strength. Equipped with two rotary printing machines, we produce innovative and trendy designs in pigment, reactive and discharge up to 10 colours with engineered repeat options.

Printing is one of our chief strength. Equipped with two rotary printing machines, we produce innovative and trendy designs in pigment, reactive and discharge up to 10 colours with engineered repeat options.

All Over Rotary Printing capacity - 12 Tonnes / day

Our garment spot printing division facilitates pigment and Plastizol prints on Sroke, Askme, MHM machines from Austria, Portugal, Taiwan and India. We are also capable of thermal transfer printing, flock printing and specialized prints using latest print techniques as Sublimation Printing and Digital Printing.

Our printing machines are capable of creating trendy and delicate designs and it is one of our biggest fortes.

"Garmenting" is a term related to the process of making garments, which are clothing items such as shirts, pants, dresses, and outerwear. Garmenting involves various stages, including designing, pattern making, cutting fabric, sewing, and finishing. This term is often used in the textile and fashion industry to refer to the production of clothing. It encompasses all the steps from the initial concept and design of a garment to its final production and distribution. The term "garmenting" can be used in the context of manufacturing and producing clothing on a large scale.

"Garmenting" is a term related to the process of making garments, which are clothing items such as shirts, pants, dresses, and outerwear. Garmenting involves various stages, including designing, pattern making, cutting fabric, sewing, and finishing. This term is often used in the textile and fashion industry to refer to the production of clothing. It encompasses all the steps from the initial concept and design of a garment to its final production and distribution. The term "garmenting" can be used in the context of manufacturing and producing clothing on a large scale.

Finishing refers to the final steps in the manufacturing process of clothing and textiles. It involves a series of operations that enhance the appearance, quality, and functionality of garments. Garment finishing can significantly affect the overall look and feel of the product, and it plays a crucial role in ensuring that the clothing meets industry standards and customer expectations.

Finishing refers to the final steps in the manufacturing process of clothing and textiles. It involves a series of operations that enhance the appearance, quality, and functionality of garments. Garment finishing can significantly affect the overall look and feel of the product, and it plays a crucial role in ensuring that the clothing meets industry standards and customer expectations.

finishing is a critical step in the textile and clothing industry, as it can greatly impact the perceived quality and appeal of a product. Manufacturers often employ skilled workers and quality control measures to ensure that garments meet the necessary standards and customer expectations before they reach the market.

Pressing and Ironing: This process involves the use of steam irons or pressing machines to remove wrinkles and creases from the garment, giving it a smooth and crisp appearance.

Pressing and Ironing: This process involves the use of steam irons or pressing machines to remove wrinkles and creases from the garment, giving it a smooth and crisp appearance.

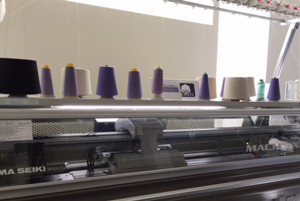

Our knitting plants, with Circular & Flat Knitting machines imported from Europe and Asia knit a varieties of fabrics - Jersey, Rib, Interlock, Pique, Feeder & Auto Stripes, Jacquards, with Lycra, flat knit collars, waffle, Fleece in all gauge and feeders.

Our knitting plants, with Circular & Flat Knitting machines imported from Europe and Asia knit a varieties of fabrics - Jersey, Rib, Interlock, Pique, Feeder & Auto Stripes, Jacquards, with Lycra, flat knit collars, waffle, Fleece in all gauge and feeders.

The entire fabric produce in house is suitable enough capacity to meet our requirement .

We are capable of producing all kind of specialty fabrics and performance technical fabrics.

Our embroidery divisions have sophisticated Japanese and German machines using CAD/CAM designing, which enable mass scale execution of intricate embroidery in upto 9 colours with, Laser cut & Sequence, with latest technology.

Our embroidery divisions have sophisticated Japanese and German machines using CAD/CAM designing, which enable mass scale execution of intricate embroidery in upto 9 colours with, Laser cut & Sequence, with latest technology.

We have a state of the art design studio equipped with.,

We have a state of the art design studio equipped with.,

Virtual Fit Simulation

Garment finishing often includes a quality control check to inspect for any defects, stitching issues, loose threads, or other imperfections that need to be corrected before the garment is released to the market.

Garment finishing often includes a quality control check to inspect for any defects, stitching issues, loose threads, or other imperfections that need to be corrected before the garment is released to the market.

Garment packing refers to the process of preparing and packaging clothing items for storage, transportation, or retail sale. Proper garment packing is essential to protect clothing from damage, maintain their quality, and present them attractively to customers.

Garment packing refers to the process of preparing and packaging clothing items for storage, transportation, or retail sale. Proper garment packing is essential to protect clothing from damage, maintain their quality, and present them attractively to customers.